How Long Does It Take to Build a Dunster House Log Cabin?

Building a Dunster House log cabin is an exciting project for homeowners seeking additional space or a peaceful retreat. The Dunster House log cabin construction time varies depending on multiple factors, including site preparation, complexity of design, and individual building skills.

Potential cabin owners often wonder about the log cabin assembly duration, which can range from a few days to several weeks. This comprehensive guide will explore the intricate details of constructing a Dunster House log cabin, helping you understand the entire process from planning to completion.

Factors such as ground preparation, foundation work, weather conditions, and your personal building expertise will significantly impact the overall construction timeline. Our expert insights will provide a clear roadmap for your log cabin project.

Inhaltsverzeichnis

Key Takeaways

- Typical Dunster House log cabin construction time ranges between 1-4 weeks

- Site preparation is crucial for efficient assembly

- Professional skills can dramatically reduce construction duration

- Weather plays a significant role in building timelines

- Proper planning minimises potential delays

Understanding Dunster House Log Cabin Basics

Exploring the world of Dunster House log cabins reveals a fascinating range of options for homeowners and garden enthusiasts. These versatile structures offer unique solutions for additional living spaces, home offices, or recreational areas.

Dunster House provides an impressive selection of log cabin types designed to meet various needs and preferences. Each cabin combines quality craftsmanship with practical design, ensuring durability and aesthetic appeal.

Exploring Log Cabin Varieties

The range of Dunster House log cabin types includes:

- Garden Studios: Compact spaces perfect for home offices or creative retreats

- Residential Cabins: Larger structures suitable for additional living accommodation

- Leisure Cabins: Recreational spaces for relaxation and entertainment

- Storage Cabins: Practical solutions for garden equipment and outdoor storage

Standard Features and Construction Materials

Construction materials play a crucial role in the quality and longevity of Dunster House log cabins. Typically, these structures utilise:

- Scandinavian pine timber

- Pressure-treated wooden frames

- High-grade insulation materials

- Robust roofing solutions

Specification Highlights

Key log cabin features include:

- Interlocking log construction

- Double-glazed windows

- Adjustable foundation systems

- Customisable interior configurations

Understanding these fundamental aspects helps potential buyers make informed decisions about their Dunster House log cabin investment.

Essential Pre-Construction Planning Steps

Successful log cabin pre-construction planning is the foundation of a smooth Dunster House preparation process. Careful preliminary steps can dramatically reduce potential challenges and streamline your entire building project.

Before breaking ground, homeowners must focus on several critical aspects of log cabin pre-construction planning:

- Site assessment and selection

- Detailed architectural drawings

- Permit acquisition

- Budget verification

- Material procurement

Dunster House preparation requires meticulous attention to location-specific details. Evaluate your plot’s topography, soil composition, and drainage characteristics. Understanding these elements helps prevent future structural complications.

Key considerations during log cabin pre-construction planning include:

- Checking local building regulations

- Conducting comprehensive site surveys

- Determining precise cabin positioning

- Verifying utility connections

- Assessing potential environmental impacts

Professional consultation during the initial planning phase can save significant time and resources in the long run. Engage with local architects or Dunster House specialists who understand regional building requirements and can provide expert guidance.

Thorough pre-construction planning transforms potential obstacles into manageable challenges.

A strategic approach to Dunster House preparation ensures your log cabin project starts on solid ground, minimising unexpected delays and maximising construction efficiency.

Site Preparation and Foundation Requirements

Preparing the perfect site for your Dunster House log cabin is a critical first step in ensuring a stable and long-lasting structure. Log cabin site preparation involves careful planning and precise execution to create a solid foundation that will support your new outdoor space.

Before beginning any construction, you’ll need to focus on three key aspects of ground preparation:

- Ground levelling for a stable base

- Selecting appropriate foundation types

- Implementing effective drainage solutions

Ground Levelling and Base Work

Ground levelling is the cornerstone of successful log cabin installation. Uneven terrain can lead to structural issues and potential damage over time. Professional landscapers recommend using a spirit level and laser measuring tools to ensure absolute precision during ground levelling.

“A perfectly level ground is the foundation of a stable log cabin” – Professional Landscaping Expert

Foundation Types and Installation Time

Different foundation installation methods suit various terrains and log cabin designs. Your choice will impact both construction time and long-term structural integrity.

| Foundation Type | Installation Time | Best Suited For |

|---|---|---|

| Concrete Slab | 2-3 days | Flat, stable ground |

| Pier Foundation | 1-2 days | Sloped or uneven terrain |

| Gravel Base | 1 day | Temporary or movable structures |

Drainage Considerations

Proper drainage prevents water accumulation around your log cabin’s foundation. Install French drains or create slight gradients to direct water away from the structure, protecting your investment from potential water damage.

How Long Does It Take to Build a Dunster House Log Cabin?

The Dunster House log cabin construction timeline varies depending on several critical factors. Typically, a standard log cabin can be completed within 4 to 8 weeks, but this average build time depends on multiple variables.

Key factors influencing construction duration include:

- Cabin size and design complexity

- Site preparation quality

- Number of skilled workers

- Weather conditions

- Availability of materials

For smaller, simpler log cabins, the build process might take as little as 3-4 weeks. More intricate designs with additional features could extend the timeline to 10-12 weeks. Professional builders with extensive experience can typically streamline the Dunster House log cabin construction timeline more efficiently.

Professional tip: Always factor in potential weather-related delays when planning your log cabin construction project.

The breakdown of typical construction stages includes:

- Foundation preparation: 3-5 days

- Frame erection: 1-2 weeks

- Roofing installation: 3-5 days

- Interior finishing: 2-3 weeks

Homeowners should consult directly with Dunster House specialists to get a precise estimate tailored to their specific log cabin requirements.

Tools and Equipment Needed for Assembly

Preparing the right log cabin construction tools and Dunster House assembly equipment is crucial for a successful and efficient log cabin build. Proper tool selection can significantly reduce construction time and ensure a high-quality finish.

Essential Building Tools

Every log cabin construction project requires a specific set of core tools. Professional builders recommend having the following Dunster House assembly equipment ready before starting:

- Circular saw for precise timber cutting

- Power drill with multiple drill bits

- Hammer and rubber mallet

- Spirit level for ensuring accurate alignment

- Measuring tape and carpenter’s square

- Ladder for reaching higher sections

Optional Equipment for Easier Construction

While not mandatory, certain additional tools can streamline the log cabin assembly process:

- Laser level for perfect horizontal alignment

- Pneumatic nail gun

- Electric screwdriver

- Scaffolding for complex roof installations

Safety Gear Requirements

Safety should always be a priority during log cabin construction. Essential safety gear includes:

| Safety Item | Purpose |

|---|---|

| Safety glasses | Eye protection from sawdust and debris |

| Hard hat | Head protection during construction |

| Steel-toed boots | Foot protection from heavy materials |

| Work gloves | Hand protection and improved grip |

| Ear defenders | Protection from loud power tool noise |

Investing in quality tools and safety equipment will make your Dunster House log cabin construction smoother and more enjoyable.

Building Team Requirements and Skill Levels

Choosing the right log cabin construction team can make or break your Dunster House log cabin project. The decision between DIY vs professional assembly depends on several critical factors that impact your overall success and budget.

When considering a log cabin construction team, skill levels play a crucial role. Professional builders bring expertise that DIY enthusiasts might lack. They understand nuanced construction techniques specific to log cabin builds.

- Professional assembly ensures precise structural integrity

- DIY approaches can save money but require significant technical knowledge

- Skill levels vary across different construction stages

The complexity of log cabin construction demands specific competencies. Professionals typically possess:

- Carpentry expertise

- Structural engineering understanding

- Specialised log fitting techniques

- Advanced tool management

| Skill Level | DIY Capability | Professional Recommendation |

|---|---|---|

| Beginner | Limited | Full professional support |

| Intermediate | Partial self-assembly | Guided professional assistance |

| Advanced | Complete self-assembly | Minimal professional oversight |

Ultimately, your log cabin construction team’s composition will determine project success. Careful evaluation of personal skills against project complexity helps make an informed decision.

Weather Considerations and Best Building Seasons

Successful log cabin construction in the UK depends significantly on understanding seasonal weather patterns. The log cabin construction weather plays a crucial role in determining project timelines and overall build quality.

Selecting the best time to build in UK requires careful planning and strategic timing. Different seasons present unique challenges and opportunities for log cabin assembly.

Impact of Different Weather Conditions

Weather conditions directly influence the construction process of log cabins. Specific factors can significantly affect building progress:

- Rainfall can delay foundation work

- Extreme temperatures impact material handling

- Wind speeds affect timber transportation

- Humidity levels influence wood treatment

Optimal Building Months in the UK

The prime months for log cabin construction in the United Kingdom typically span from late spring to early autumn. These periods offer more stable weather conditions.

| Season | Construction Suitability | Key Considerations |

|---|---|---|

| Spring (April-May) | Good | Moderate temperatures, reducing moisture risks |

| Summer (June-August) | Excellent | Longest daylight hours, minimal precipitation |

| Autumn (September-October) | Moderate | Cooling temperatures, potential increased rainfall |

| Winter (November-March) | Challenging | High precipitation, freezing temperatures |

Weather-Related Delays

Potential weather-related delays can extend project timelines. Professionals recommend building buffer time into construction schedules to account for unexpected meteorological interruptions.

- Monitor long-range weather forecasts

- Prepare alternative indoor work during poor conditions

- Use protective coverings for materials

- Schedule critical work during stable weather windows

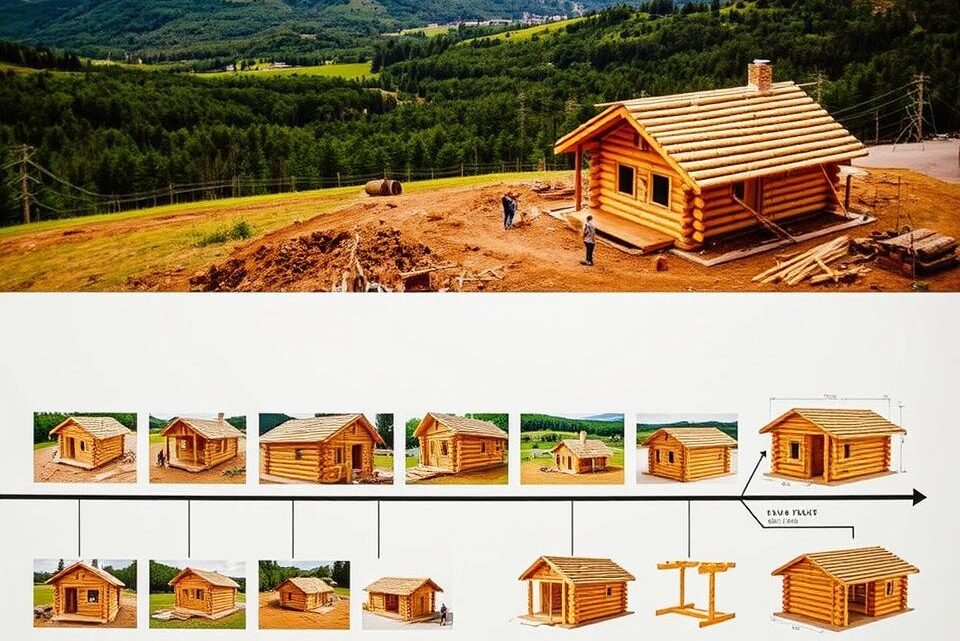

Step-by-Step Construction Timeline

The Dunster House log cabin build process involves carefully planned construction stages that transform raw materials into a beautiful wooden structure. Understanding each step helps homeowners prepare for the exciting journey of creating their dream cabin.

Successful log cabin construction requires meticulous planning and precise execution. The typical construction stages can be broken down into several key phases:

- Site Preparation (2-3 days)

- Ground levelling

- Foundation marking

- Clearing vegetation

- Foundation Work (3-5 days)

- Base installation

- Concrete or gravel base preparation

- Levelling and compacting

- Log Wall Assembly (5-7 days)

- Precise log placement

- Interlocking techniques

- Weatherproofing

Each construction stage requires specific skills and attention to detail. Professionals recommend allocating approximately 2-3 weeks for the entire Dunster House log cabin build process.

“Precision during construction ensures a durable and beautiful log cabin that will last for generations.”

Key factors influencing construction timeline include:

- Weather conditions

- Team expertise

- Complexity of design

- Material availability

| Construction Stage | Estimated Duration | Key Activities |

|---|---|---|

| Site Preparation | 2-3 days | Ground levelling, marking |

| Foundation Work | 3-5 days | Base installation, compacting |

| Log Wall Assembly | 5-7 days | Log placement, weatherproofing |

Pro tip: Always consult with experienced log cabin builders to get the most accurate timeline for your specific project.

Common Challenges and Solutions During Assembly

Building a log cabin involves intricate processes that can present various log cabin construction problems. Understanding potential assembly troubleshooting techniques helps homeowners navigate challenges effectively and ensure a smooth construction experience.

During log cabin assembly, several common issues may arise that require careful attention and strategic resolution:

- Log Misalignment: Precise cutting and fitting are crucial to prevent gaps and structural weaknesses

- Uneven Foundation: Proper ground preparation prevents future structural complications

- Moisture Penetration: Careful sealing techniques protect against water damage

- Timber Warping: Selecting quality materials and proper storage minimises deformation risks

Practical Troubleshooting Strategies

Successful assembly troubleshooting requires systematic problem-solving approaches. Experienced builders recommend:

- Double-checking measurements before cutting

- Using specialised log cabin construction tools

- Implementing gradual adjustments during assembly

- Consulting manufacturer guidelines

Professional Support Options

When log cabin construction problems become complex, professional assistance ensures optimal results. Reputable manufacturers often provide:

- Technical support helplines

- Detailed installation guidance

- Optional on-site consultation services

- Comprehensive assembly video tutorials

By understanding potential challenges and accessing appropriate resources, DIY enthusiasts can successfully navigate log cabin construction with confidence.

Post-Construction Finishing and Treatment

Completing a log cabin involves critical log cabin finishing steps that protect your investment and enhance its aesthetic appeal. The final touches are not merely cosmetic but essential for long-term durability and performance.

Wood treatment plays a pivotal role in preserving your log cabin’s structural integrity. The process involves several key stages:

- Cleaning the wood surface thoroughly

- Inspecting for any imperfections or damage

- Applying protective sealants

- Implementing weather-resistant treatments

Professional wood treatment typically requires 2-3 days, depending on the cabin’s size and complexity. Rushing these final touches can compromise the wood’s protection against moisture, UV rays, and potential wood decay.

Different wood treatments offer unique benefits:

- Clear sealants: Maintain natural wood appearance

- Stained treatments: Add colour and enhanced protection

- Preservative oils: Deep wood penetration and long-lasting defence

Selecting appropriate wood treatment methods ensures your log cabin remains resilient against British weather conditions, preventing potential structural issues and maintaining its aesthetic charm for years to come.

Building Regulations and Planning Permission Timeline

Navigating the log cabin planning permission landscape can be complex for UK homeowners. Understanding the building regulations timeline is crucial for a smooth construction process. Local authorities have specific requirements that must be carefully addressed before and during your Dunster House log cabin project.

The journey to obtaining log cabin planning permission involves several key stages:

- Initial site assessment

- Preparing detailed documentation

- Submitting application to local planning authority

- Compliance verification

Local Authority Requirements

Different local councils have varying regulations for log cabin construction. Typically, you’ll need to provide:

- Detailed site plans

- Architectural drawings

- Proof of land ownership

- Environmental impact assessment

Documentation Processing Time

The building regulations timeline can vary depending on your local authority’s workload and the complexity of your project. Most applications take between 8 to 12 weeks for complete processing.

| Application Stage | Typical Duration |

|---|---|

| Initial Review | 2-3 weeks |

| Detailed Assessment | 4-6 weeks |

| Final Approval | 2-3 weeks |

Compliance Checks

Local authorities conduct thorough compliance checks to ensure your log cabin meets all building regulations. This includes verifying structural integrity, safety standards, and adherence to local planning guidelines.

Pro tip: Engage with your local planning office early to streamline the log cabin planning permission process.

Conclusion

Building a Dunster House log cabin requires careful planning and strategic execution. The construction time typically ranges between 2-6 weeks, depending on various critical factors such as site preparation, weather conditions, and team expertise. A successful Dunster House log cabin build depends on understanding these key construction time factors and preparing thoroughly.

Your log cabin project demands meticulous attention to detail, from initial site assessment through final finishing stages. Local regulations, foundation work, and seasonal considerations will significantly impact your overall timeline. Professional preparation minimises potential delays and ensures a smoother building experience.

Armed with comprehensive knowledge about Dunster House log cabin construction, homeowners can approach their project with confidence. By anticipating potential challenges and understanding each stage of development, you’ll be well-positioned to create a beautiful, functional log cabin that meets your specific requirements and stands the test of time.

Ultimately, a successful log cabin build is about balancing practical considerations with your personal vision. With proper planning, the right team, and realistic expectations, your Dunster House log cabin can become an exceptional addition to your property.

FAQ

How long does it typically take to build a Dunster House log cabin?

The construction time varies depending on factors like cabin size, complexity, and your experience level. On average, a standard log cabin can take between 1-2 weeks for DIY builders, while professional teams might complete the project in 3-5 days.

Do I need planning permission for a Dunster House log cabin?

Planning permission requirements depend on the cabin’s size, location, and intended use. In many cases, log cabins fall under permitted development rights, but it’s crucial to check with your local planning authority to confirm specific regulations in your area.

What tools will I need to build a log cabin?

Essential tools include a spirit level, drill, hammer, saw, measuring tape, and safety equipment. Depending on the cabin’s complexity, you might also need specialised tools like a pneumatic nailer or specific wood-working equipment.

Can I build a Dunster House log cabin by myself?

While it’s possible to build a log cabin as a DIY project, your skill level and experience are crucial. Some people successfully complete the project independently, but others might benefit from professional assistance or at least having an experienced friend help.

What are the best months for building a log cabin in the UK?

The optimal building months are typically between May and September, when weather conditions are more stable and dry. Avoid winter months due to potential rain, cold temperatures, and increased risk of weather-related construction delays.

How much does site preparation impact construction time?

Site preparation is critical and can significantly affect your overall construction timeline. Proper ground levelling, foundation work, and drainage considerations might add 2-4 days to your project, depending on the site’s initial condition.

What wood treatments are recommended after construction?

Protective wood treatments are essential for longevity. Recommended options include water-resistant sealants, wood preservatives, and exterior-grade paints or stains. Allow 1-2 days for proper application and drying between coats.

Are there any specific safety considerations during log cabin construction?

Safety is paramount. Always wear protective gear like safety glasses, gloves, and sturdy footwear. Ensure you have proper lifting techniques, use scaffolding or ladders correctly, and have a first aid kit on hand during the construction process.

How do weather conditions affect log cabin construction?

Weather can significantly impact construction timelines. Rain can delay work, extreme temperatures can affect wood fitting, and high humidity might influence wood treatment processes. Always monitor weather forecasts and plan accordingly.

What should I do if I encounter problems during assembly?

If you face challenges, consult Dunster House’s customer support, review the instruction manual carefully, or consider hiring a professional carpenter for specific troubleshooting. Many issues can be resolved with patience and careful examination.